Choosing a garage floor coating in the Great Lakes State isn’t just about picking a color. It’s about choosing a material that can survive a 50-degree temperature swing in 24 hours. For many Michigan homeowners, the decision comes down to Epoxy vs. Polyurea.

While traditional epoxy has been the “standard” for years, modern polyurea technology has changed the game for those seeking a durable garage floor coating Michigan weather can’t crack. At TruTech Concrete Coatings, we believe in transparency. To help you protect your investment, we’ve put together this definitive guide comparing these two powerhouses.

The Chemistry: How They Work

To understand why one coating fails while the other thrives, we have to look at the science.

Epoxy Coatings

Epoxy is a thermosetting resin. It’s created by mixing a resin with a polyamine hardener. When applied, it creates a rigid, cross-linked bond. Think of epoxy as a hard, protective shell—much like a ceramic plate. It’s tough, but it doesn’t like to bend.

Polyurea Coatings

Polyurea is derived from the reaction of an isocyanate and a synthetic resin blend. Unlike epoxy, polyurea creates an elastomeric structure. If epoxy is like a ceramic plate, polyurea is like a high-tech armor vest. It is naturally flexible and much more impact-resistant, making it a superior polyurea garage floor Michigan solution for active families.

The “Michigan Factor”: Temperature & Curing

The biggest weakness of an epoxy garage floor Michigan installation is the climate.

- Epoxy’s Temperature Problem: Epoxy generally requires temperatures above 50°F to cure. In Michigan, that limits your installation window significantly. If it’s 40°F in your garage in November, epoxy simply won’t cure—it will remain a sticky, ruined mess for months.

- Polyurea’s Winter Advantage: Polyurea is a beast in the cold. It can be applied in temperatures as low as -20°F. Whether you are in Detroit or the Upper Peninsula, we can provide a Michigan garage floor upgrade even in the dead of winter.

- Speed of Install: Epoxy takes 2–5 days to fully cure before you can park your car. Polyurea offers a one day garage floor Michigan experience. We apply it in the morning, and you can park your truck on it by the next evening.

Flexibility: Surviving the Freeze-Thaw Cycle

Michigan concrete doesn’t stay still. The moisture in our soil freezes and thaws, causing the concrete slab to expand and contract.

- Epoxy’s Rigidity: Because epoxy is brittle, when the concrete underneath moves, the epoxy often cracks or delaminates (peels). This is the most common reason for garage floor repair Michigan calls—homeowners tired of seeing their DIY epoxy kits flake off.

- Polyurea’s Elasticity: Polyurea is up to 10x more flexible than epoxy. It bridges small hairline cracks and moves with your home. This flexibility is why it’s the best garage floor coating Michigan homeowners can choose for long-term peace of mind.

UV Stability and “Ambering”

Have you ever seen a garage floor that looks yellow near the door? That’s “ambering,” and it’s a hallmark of epoxy. Epoxy reacts poorly to UV rays. Even a little bit of Michigan sunlight peeking under your garage door will eventually turn a gray epoxy floor a sickly yellow.

At TruTech, our polyaspartic garage floor Michigan systems are 100% UV stable. Polyaspartic is a high-end version of polyurea used as a topcoat. It won’t yellow, won’t fade, and maintains its “showroom shine” for decades.

Adhesion: The Secret is in the Prep

The competitor’s blog mentions that epoxy “seeps” into the concrete better because it dries slower. While that sounds logical, it’s a bit of a myth.

The truth? Adhesion is all about Concrete Surface Profile (CSP).

Whether we are installing Michigan residential floor coatings or high-traffic Michigan commercial floor coatings, we use industrial diamond grinders to open the pores of your concrete. When the concrete is prepped to a CSP 2 or 3 rating, polyurea bonds so deeply that the concrete will actually break before the coating peels off.

Chemical and Salt Resistance

Michigan roads are coated in salt and liquid brine for five months a year. When that slush melts off your car, it pools on your garage floor.

- Epoxy has good chemical resistance, but salt can eventually dull the finish and find its way through microscopic cracks.

- Polyurea is virtually impenetrable. It stands up to road salt, gasoline, oil, and even battery acid, making it the premier choice for garage floor solutions Michigan.

Cost vs. Value: The Real ROI

Let’s talk about the “average cost” transparently.

- Epoxy is cheaper upfront. If you are flipping a house or on a very tight budget, epoxy might be tempting.

- Polyurea is a lifetime investment. Because you don’t have to redo it every 5 years, the “cost per year” of a polyurea floor is actually lower than epoxy. It adds real, apprasable value to your Michigan home.

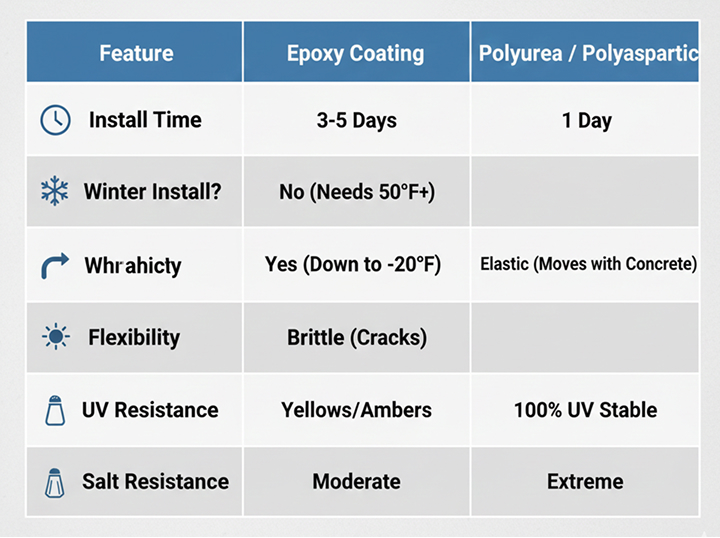

Summary Table: Why Polyurea Outperforms Epoxy in Michigan

|

Feature |

Epoxy Coating |

Polyurea / Polyaspartic |

|

Install Time |

3-5 Days |

1 Day |

|

Winter Install? |

No (Needs 50°F+) |

Yes (Down to -20°F) |

|

Flexibility |

Brittle (Cracks) |

Elastic (Moves with Concrete) |

|

UV Resistance |

Yellows/Ambers |

100% UV Stable |

|

Salt Resistance |

Moderate |

Extreme |

Why TruTech is the Local Leader

When you search for garage floor repair Michigan, you want a team that understands local geology and weather patterns. We don’t use “one size fits all” kits. We customize our resin blends to match the moisture levels and condition of your specific slab.

Whether you’re looking for Michigan commercial floor coatings for a warehouse in Troy or a beautiful flake finish for your home in Ann Arbor, we provide the industrial-grade protection you deserve.

Ready for a Floor That Actually Lasts?

Don’t let another Michigan winter eat away at your concrete. Move past the “cheap” epoxy options and invest in a floor that works as hard as you do.